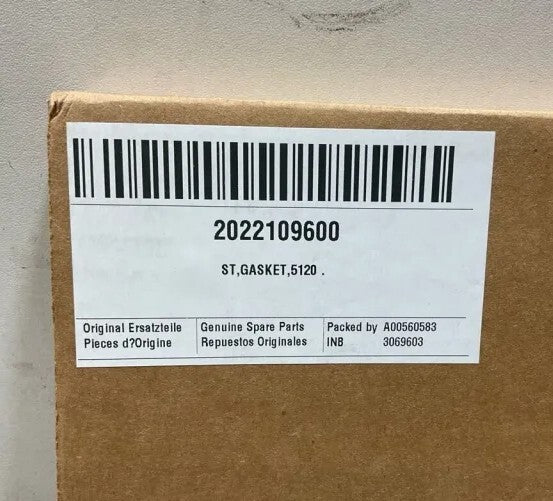

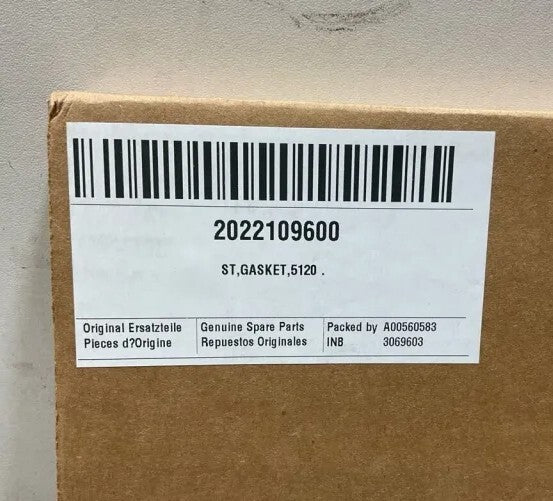

QUINCY 2022109600 SET, GASKET, 5120

QUINCY 2022109600 SET, GASKET, 5120

Quincy Replacement Gasket Set Part 2022109600

Gaskets

Gaskets are critical components in compressor systems, serving to create a seal between two or more surfaces to prevent the leakage of fluids or gases. They are typically used to maintain airtight conditions, which is essential for the efficient operation of a compressor.

Functions of Gaskets in Compressor Systems

-

Sealing – The primary function of a gasket is to prevent leaks by providing a seal between mating surfaces. This is especially important in components like cylinder heads, valve plates, and flanges.

-

Vibration Dampening – Gaskets can absorb some vibration, reducing the potential for mechanical noise and wear on compressor components.

-

Compensating for Irregularities – They fill the gaps and compensate for minor surface irregularities between the mating parts, ensuring a tight seal even if the surfaces are not perfectly smooth.

Types of Gaskets Used in Compressors

-

Metallic Gaskets

-

Applications: Used in high-pressure and temperature situations where resilience and strength are required, such as in flanged connections.

-

Materials: Common materials include stainless steel or other alloys.

-

-

Non-Metallic Gaskets

-

Rubber Gaskets: Made from materials like neoprene or nitrile, ideal for applications involving lower pressures and temperatures.

-

Applications: Suitable for areas where flexibility and chemical resistance are necessary, such as O-rings and certain flange connections.

-

-

Composite Gaskets

-

Construction: Combine metal and non-metal layers for enhanced sealing capabilities.

-

Applications: Often used in head gaskets where strength and compliance are critical.

-

Considerations for Selecting Gaskets

-

Material Compatibility – The gasket material should be compatible with the fluid or gas being compressed and any other environmental conditions, such as temperature, pressure, and exposure to chemicals.

-

Operating Conditions – Choose the appropriate gasket based on the pressure and temperature ranges of the application to ensure reliable sealing and prevent degradation.

-

Surface Conditions – Ensure that the surfaces to be sealed are clean, flat, and free from damage to maximize gasket efficacy.

-

Gasket Thickness and Compressibility – The chosen gasket should have the right thickness and compressibility to seal effectively without excessive deformation.

-

Replacement and Maintenance – Regular inspection and maintenance should be performed to identify wear or compression sets, replacing gaskets as needed to maintain integrity and efficiency of the compressor system.

Installation Tips

-

Proper Alignment – Ensure the gasket is properly aligned between the mating surfaces to avoid leaks.

-

Torque Specifications – Follow the manufacturer’s torque specifications when securing bolts to avoid over-compression or insufficient sealing.

-

Surface Preparation – Clean and, if necessary, lightly lubricate mating surfaces to facilitate sealing and ease of future disassembly.

Summary

Gaskets are essential for maintaining the efficiency and safety of compressor systems by providing reliable seals between various components. Appropriate selection, installation, and maintenance of gaskets are crucial in preventing leaks and ensuring the long-term performance of compressors.

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share